Linear Guideway Motion Systems

2023-05-12

60 Closed-loop Servomotor

2023-05-12Screw Drive Linear Guideway

The modular system comprises the following basic elements: guide rollers, tracks (with or without in-built racks), pinions and beams.

1. Product Introduction

Linear guide ways

We design linear systems for medium and heavy payloads

Our linear systems, with their longitudinal precision guides and drive train components, provide high speed and acceleration and enable a moving mass weighing anywhere between ten kilos and several tons to be positioned with the utmost accuracy.

The modular system comprises the following basic elements: guide rollers, tracks (with or without in-built racks), pinions and beams. The assembly can be employed anywhere and has several advantages over traditional recirculation ball systems. Because of its compactness and the integrated racks for the drive, it is an excellent solution in premises where space is at a premium.

Linear guide ways provides linear motion by re-circulating rolling elements between a profiled rail and a bearing block. The coefficient of friction on a linear guide way is only 1/50 compared to a traditional slide and they are able to take loads in all directions. With these features, a linear guide way can achieve high precision and greatly enhanced moving accuracy. We offer multiple linear guide way series, each featuring different options for sizes, loading capabilities, accuracies, and more.

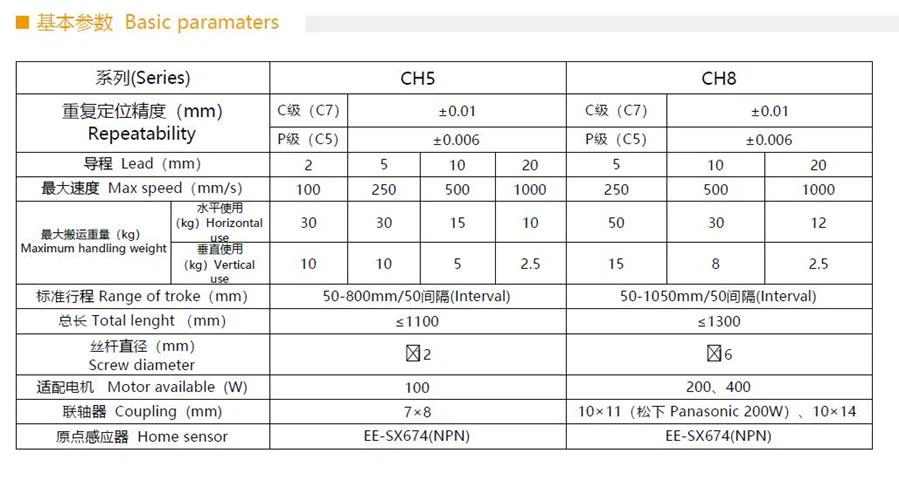

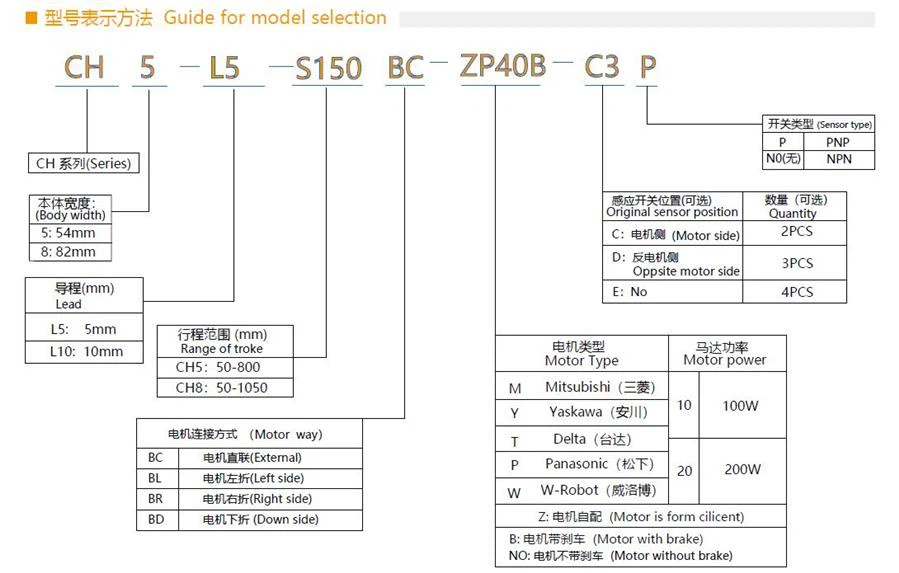

2. Product Parameter (specification)

CH8

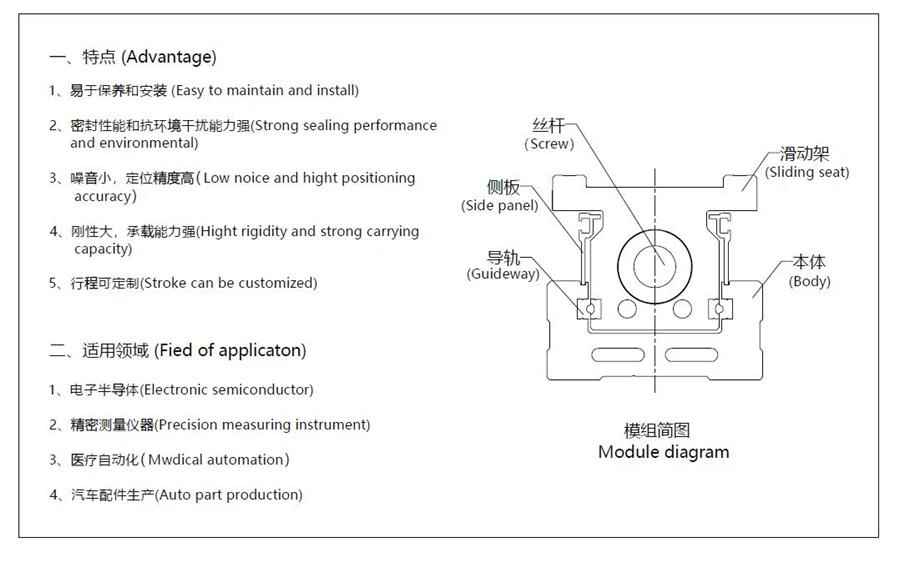

3. Product feature and application:

4. Production detail:

5. Product qualification:

6. Deliver, shipping and serving:

7. FAQ:

linear guideway is a design of rolling motion with a low friction coeffi cient, and the difference between dynamic and static friction is very small. Therefore, the stick-slip will not occur when submicron feeding is making.

The frictional resistance of a linear guideway is only 1/20th to 1/40th of that in a slide guide. With a linear guideway, a well lubrication can be easily achieved by supplying grease through the grease nipple on carriage or utilizing a centralized oil pumping system, thus the frictional resistance is decreased and the accuracy could be maintained for long period.

The optimum design of geometric mechanics makes the linear guideway to bear the load in all four directions, radial, reversed radial, and two lateral directions. Furthermore, the rigidity of linear guideway could be easily achieved by preloading carriage and by adding the number of carriages.

Due to the characteristic of low frictional resistance, the required driving force is much lower than in other systems, thus the power consumption is small. Moreover, the temperature rising effect is small even under high speed operation.

Compared with the high-skill required scrapping process of conventional slide guide, the linear guideway can offer high precision even if the mounting surface is machined by milling or grinding.

Moreover the interchangeability of linear guideway gives a convenience for installation and future maintenance.

Hot Tags: screw drive linear guideway, China, manufacturers, suppliers, factory, wholesale, buy, customized, bulk, in stock, Semi-closed Belt Drive Linear Actuator, Fully-closed Screw Drive Linear Actuator, Robot, XY Linear Motor, Linear Guideway Motion Systems, Dust-free Environment Belt Drive Linear Actuator