57 Stepper Servo Motor

2023-05-12

Closed Type Linear Motor

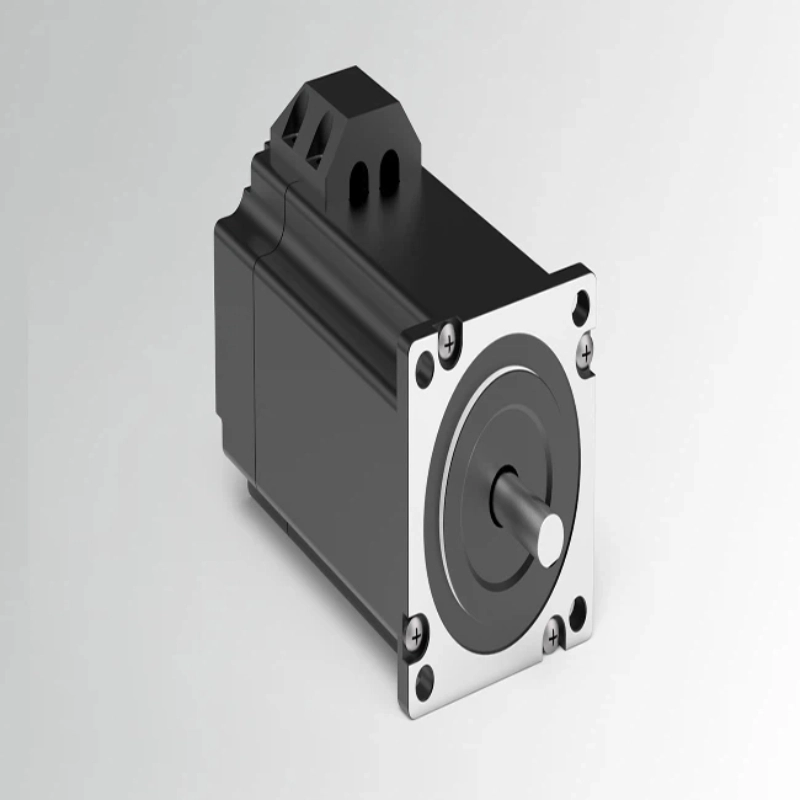

2023-05-1242 Stepping Servo Motor

Do you need stepper motors or servo motors in your business? Perhaps you need both. Although they are not as different as some might think, there are some significant differences between the two.

1. Product Introduction

What Is the Difference Between a Stepper Motor and Servo Motor?

Do you need stepper motors or servo motors in your business? Perhaps you need both. Although they are not as different as some might think, there are some significant differences between the two. If you’re not quite clear on the properties and benefits of the stepper motor vs. the servo motor, here’s a basic breakdown to help clear things up.

A stepper motor is so named because it is a motor that moves in discrete steps. These DC motors have a number of coils arranged in phases. The power source energizes each phase in sequence, causing the motor to rotate one step for each phase.

There are a number of different types of stepper motors, but they all have this basic mechanism at their base. The stepping motion of the motor allows for a great deal of precision and speed control.

A servo motor is a closed-loop motor that is linked to an encoder that provides position and speed feedback. The mechanism uses this feedback to determine its motion. The controller sends an error signal to the motor if it is not in the right position, signaling it to continue its motion until it reaches the desired position.

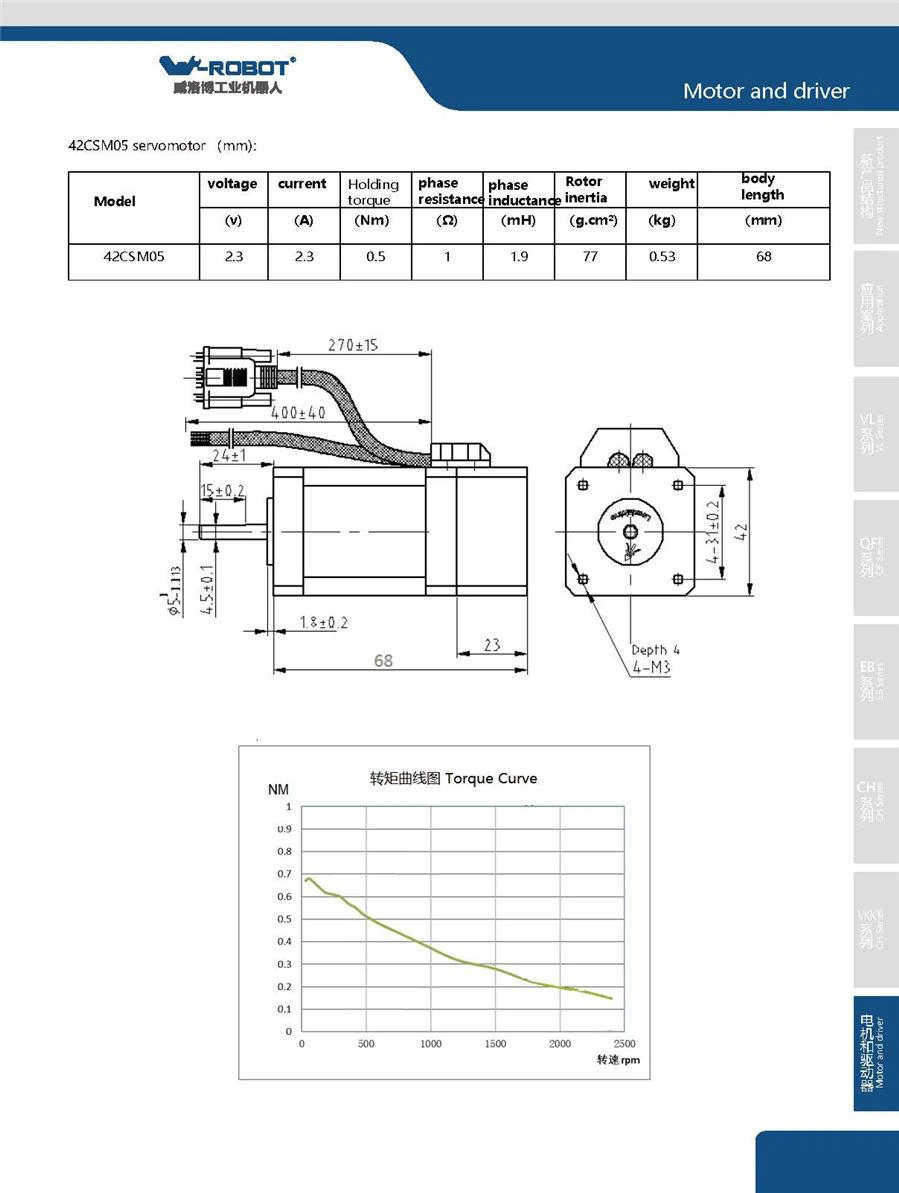

2. Product parameters.

42 stepper servo motor

3. Product qualification:

4. Deliver, shipping and serving:

5. FAQ:

Stepper Motor vs. Servo Motor

Which motor is right for your needs?

At a very basic level, if precision and control are your priorities, you will usually want a stepper motor, whereas if speed is the property you value most, a servo motor is usually better. The truth is that when properly optimized, a stepper motor can usually do the same job as a servo motor, only slower and more affordably.

However, it may be useful to dig a little deeper when researching for motors for your application. Let’s look at some more pros and cons of each type of motor.

Stability

If stability is a requirement, you will want to gravitate towards stepper motors. Servo motors tend to pulsate even at a standstill, so if you have a situation where the motor needs to hold a load still, or another application where lack of stability could interfere with the process, you should generally use a stepper motor.

Torque

You can usually get roughly the same torque from a stepper motor as from a servo motor. You will generally get higher performance from a servo, with a more flexible speed curve and an extra time-dependent peak torque rating, but again, an optimized stepper motor can usually do the same job more affordably.

Keep in mind, though, that with a servo motor you have control over the torque, while a stepper always operates at its maximum torque. This can sometimes be an advantage to the stepper, as you can often achieve maximum torque at a safer voltage.

Also note that you need the most power when it comes to stepper motors during the acceleration phase, so you need torque requirements within the nominal curve for the stepper motor.

Size

Stepper motors and servo motors are available in similar sizes. Consider, however, that the length of the motor is a factor in torque value and inertia value, so a motor of greater length may offer different performance even if it is roughly the same overall size as another motor.

Speed

As we have discussed, if speed is the priority, you need servo motors. However, in applications where the motor is generating more RPMs that you need, like in a belt drive, you can often substitute a stepper motor for a cheaper solution with the same result.

Micro-Stepping

Micro-stepping involves increasing the resolution of the motor by dividing the current between the two poles to provide half-steps when a motor offers fewer steps than you need. The name might suggest that a stepper motor is optimal for such a procedure, but servo motors are preferable, as this process results in a considerable reduction of torque in a stepper motor.

If you primarily use servo motors in your applications, you may want to take a closer look and see if you can substitute stepper motors, as these substitutions can result in considerable cost savings. By the same token, if you are not getting the desired results from your stepper motors, it is possible that servo motors can do the job better.

Hot Tags: screw drive linear guideway, China, manufacturers, suppliers, factory, wholesale, buy, customized, bulk, in stock, Semi-closed Belt Drive Linear Actuator, Fully-closed Screw Drive Linear Actuator, Robot, XY Linear Motor, Linear Guideway Motion Systems, Dust-free Environment Belt Drive Linear Actuator