General Environment Screw Drive Linear Actuator

2023-05-16

Belt Drive Linear Actuator Dual Motor

2023-05-16Electric Linear Motor

A linear motor is an electric motor that has had its stator and rotor “unrolled” thus instead of producing a torque (rotation) it produces a linear force along its length.

1. Product Introduction

A linear motor is an electric motor that has had its stator and rotor “unrolled” thus instead of producing

a torque (rotation) it produces a linear force along its length. However, linear motors are not necessarily

straight. Characteristically, a linear motor’s active section has ends, whereas more conventional motors are

arranged as a continuous loop.

Many designs have been put forward for linear motors, falling into two major categories, low-acceleration and

high-acceleration linear motors. Low-acceleration linear motors are suitable for maglev trains and other

ground-based transportation applications. High-acceleration linear motors are normally rather short, and are

designed to accelerate an object to a very high speed, for example see the coil gun.

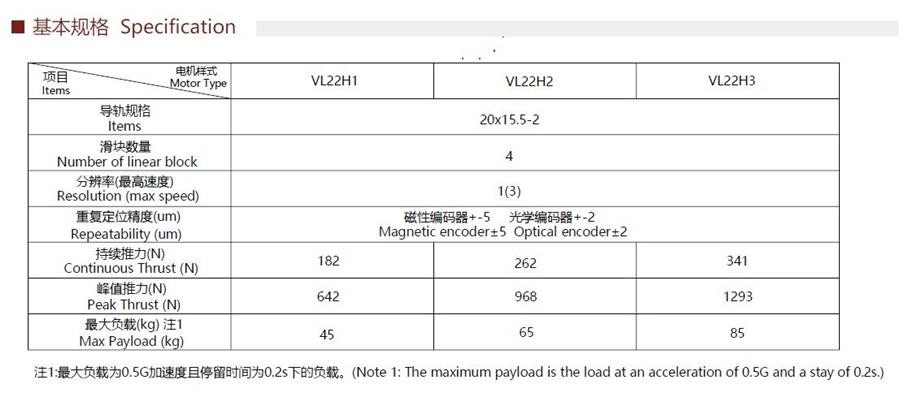

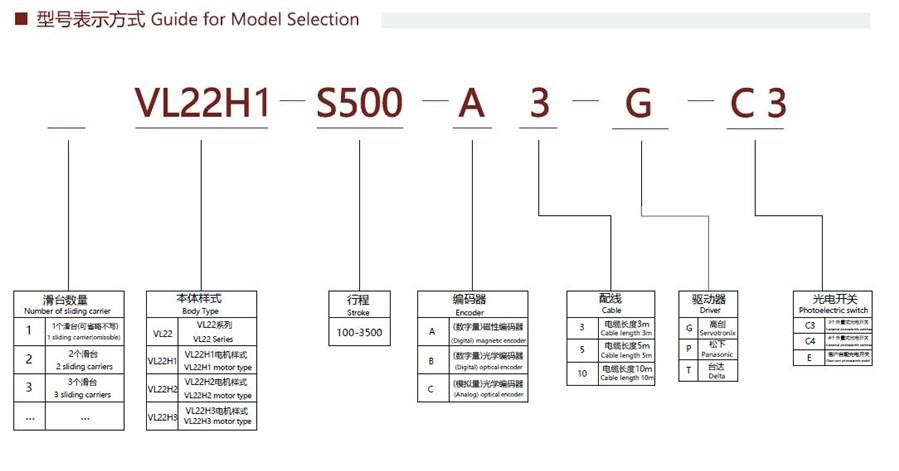

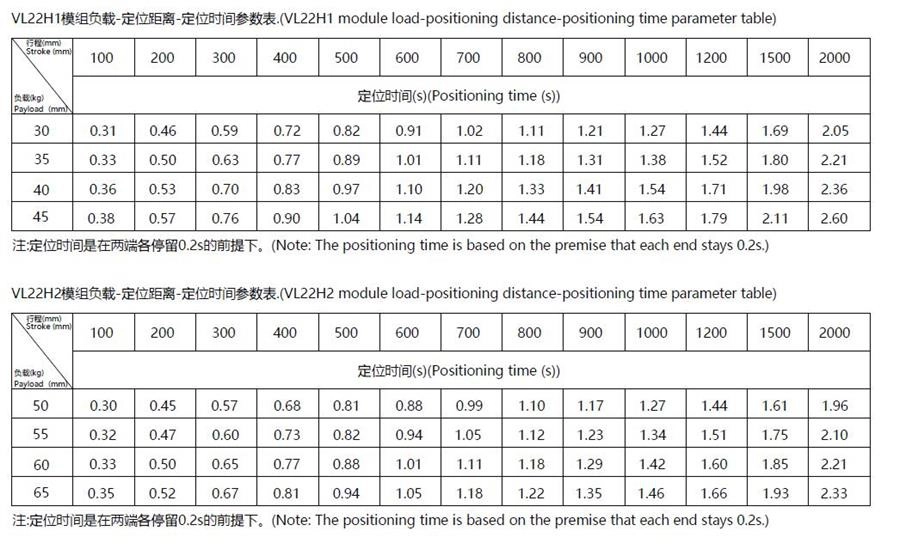

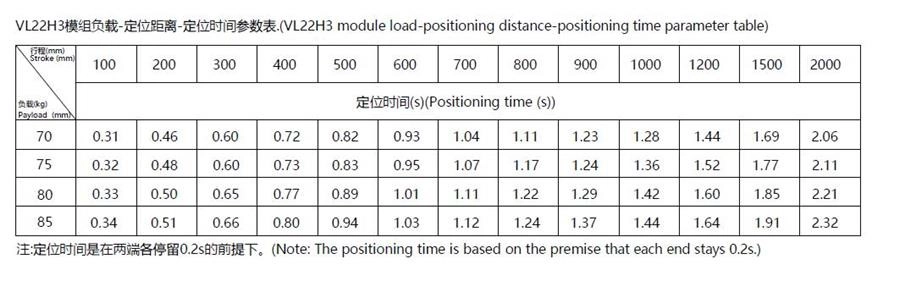

2. Product parameters:

VL22

3. Product feature and application:

4. Product qualification:

5. Deliver, shipping and serving:

6. FAQ:

Advantages of linear motors on high speed

With the development of direct drive technology, the comparison between the linear motor and the driving method of

the traditional “rotary servo motor ball screw” has attracted industry attention. Now some of the

world’s most advanced machining center manufacturers are beginning to apply on their high speed machine

tools.

In terms of accuracy, the linear motor has a simple reduction of the interpolation hysteresis due to the transmission

mechanism, positioning accuracy, reproduction accuracy, and absolute accuracy. The position detection feedback

control is higher than the “rotary servo motor ball screw” and is easy to implement. Linear motor

positioning accuracy up to 0.1μm. “Rotary servo motor ball screw” up to 2~5μm, and Claim CNC-servo

motor-no-gap coupling-thrust bearing-cooling system-high-precision rolling guide-nut seat – Workbench

closed-loop The transmission part of the whole system should be lighter and the grating accuracy should be high.

If you want to achieve high stability, the “rotary servo motor ball screw” should adopt dual-axis

drive. The linear motor is a high-heating component. It needs to adopt a strong cold Measure. To achieve the

same purpose, the linear motor has to pay more cost.

In terms of speed, the linear motor has a considerable Advantage, the linear motor speed reaches 300m/min, the

acceleration reaches 10g, the ball screw speed is 120m/min, and the acceleration is 1.5g. From the comparison of

speed and acceleration, the linear motor has considerable The advantage, and the linear motor will further

improve the speed after successfully solving the heating problem, and the “rotary servo motor ball

screw” is limited in speed and it is difficult to improve more.

In terms of life, the linear motor has a gap between the moving part and the fixed part, no contact, no wear and tear

due to the high-speed reciprocating motion of the mover, and long-term use does not change the positioning

accuracy of the motion, and is suitable for high-precision occasions. The ball screw can not guarantee the

accuracy in the high-speed reciprocating motion. Because of the high-speed friction, the wear of the screw nut

will affect the accuracy of the motion. Satisfy cannot be used for high precision requirements.

Hot Tags: semi-closed belt drive linear actuator, China, manufacturers, suppliers, factory, wholesale, buy, customized, bulk, in stock, General Environment Screw Drive Linear Actuator, Rotation Actuator, Electric Linear Cylinders, Rotary Table Actuator, Electronic Rotary Actuator, Ball Screw Electric Cylinder