Scara Electric Robot

2023-05-12

Robot Clamp Gripper

2023-05-12Clamp Type Single Robot

The Grippers are easy to install and program. The robot comes pre-configured with Gripper input/output signals which greatly reduces both set up and programming time.

1. Product Introduction

Clamp is a simple plug-and-play extension

Wide-ranging flexibility

Easy to integrate, easy to use

The Grippers are easy to install and program. The robot comes pre-configured with Gripper input/output signals which greatly reduces both set up and programming time. And the graphical user interface simplifies the testing of palletizing routines. For example a Gripper pick and-place test can be carried out with just a single click.

Faster, more accurate programming

This user-friendly, PC based software, comes pre-configured with gripper models. It allows users who have little or no robot programming experience to create programs and simulations, and design complete palletizing installations. This enables a palletizing system to be configured rather than programmed, and saves up to 80 percent in commissioning time.

Speed and precision

The Gripper-Clamp is equipped with sensors to verify the presence of cases. Their wide clamping strokes are adaptable to different case sizes. The included hook units ensure secure handling of the cases when moving at high speeds. It also comes complete with all air hoses and signal cables and is ready to plug-and play on your chosen robot model.

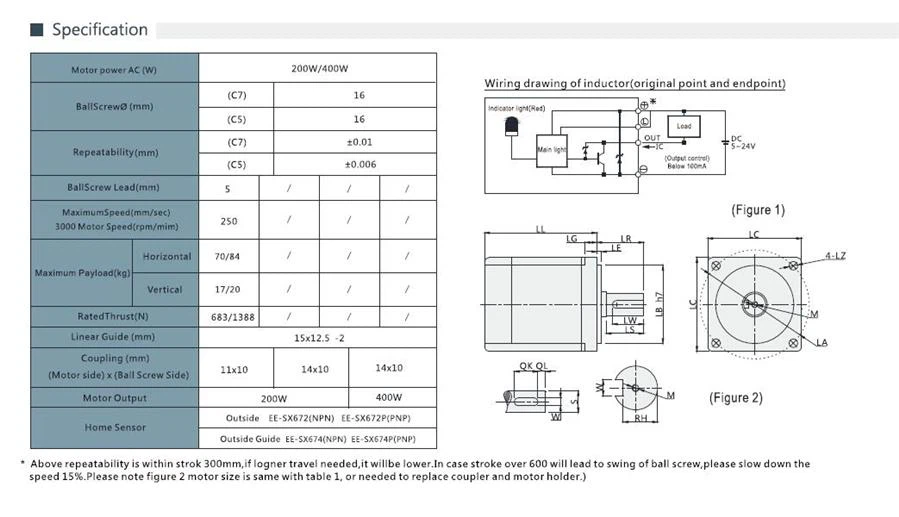

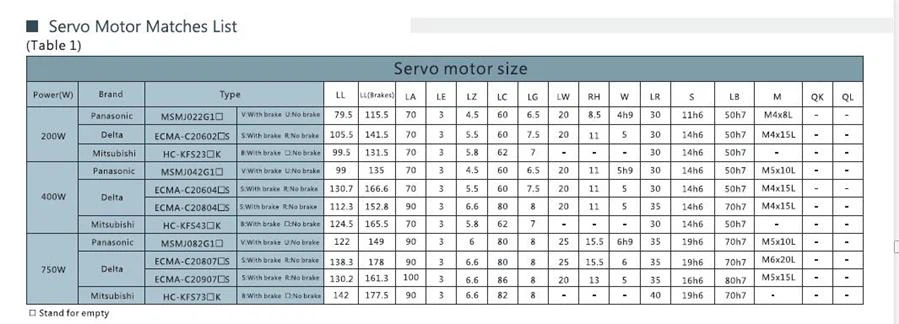

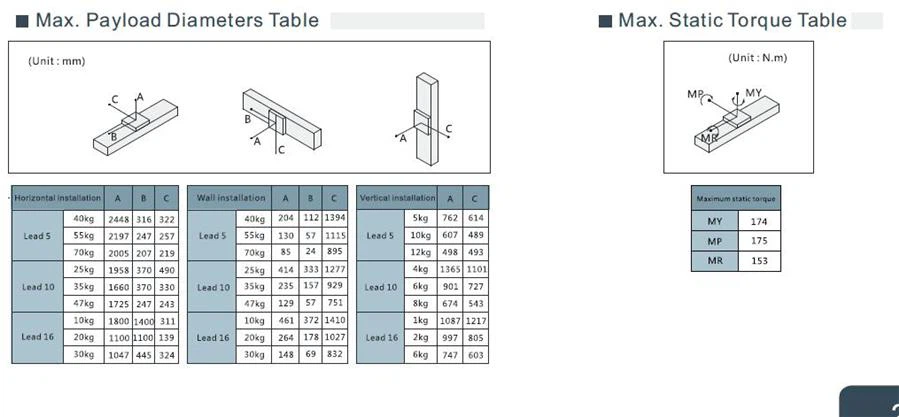

2. Product Parameter (specification)

VF12D1

3. Product feature and application:

Features and benefits

■ Wide clamping stroke adapts to different case width

■ Rubber pad to increase friction force

■ Hook unit for high speed movements

■ Sensors to verify presence / absence of cases.

■ Adjustable stationary plate and pneumatic cylinder for different case sizes.

■ Built-in pallet claw and slip sheet picker as an option.

■ Completely assembled with hoses and cables for easy plug-and-play installation.

■ Graphical User Interface (GUI) provided on robot FlexPendant for easy gripper setup, tuning, and production monitoring.

Main Application

■ Case palletizing

4. Production detail:

5. Product qualification:

6. Deliver, shipping and serving:

7. FAQ:

Grippers and Clamps are used to hold the product on a machine while some secondary operation is being done to it or it is being moved to another location on the machine. This might be a Pick & Place operation where the product is moved from one work station to another or it might be a sheet metal application to hold the metal during the bending or stamping process.

Grippers tend to be smaller and more precise than clamps which are typically used where higher forces are necessary. Gripper movement is usually either Parallel or Angular but there are specialty types of grippers such as 3 jaw grippers and pinch valves.

Clamps come in several types ranging from 2 jaw clamps to arm over clamps and twist clamps to handle a wide variety of work holding applications.